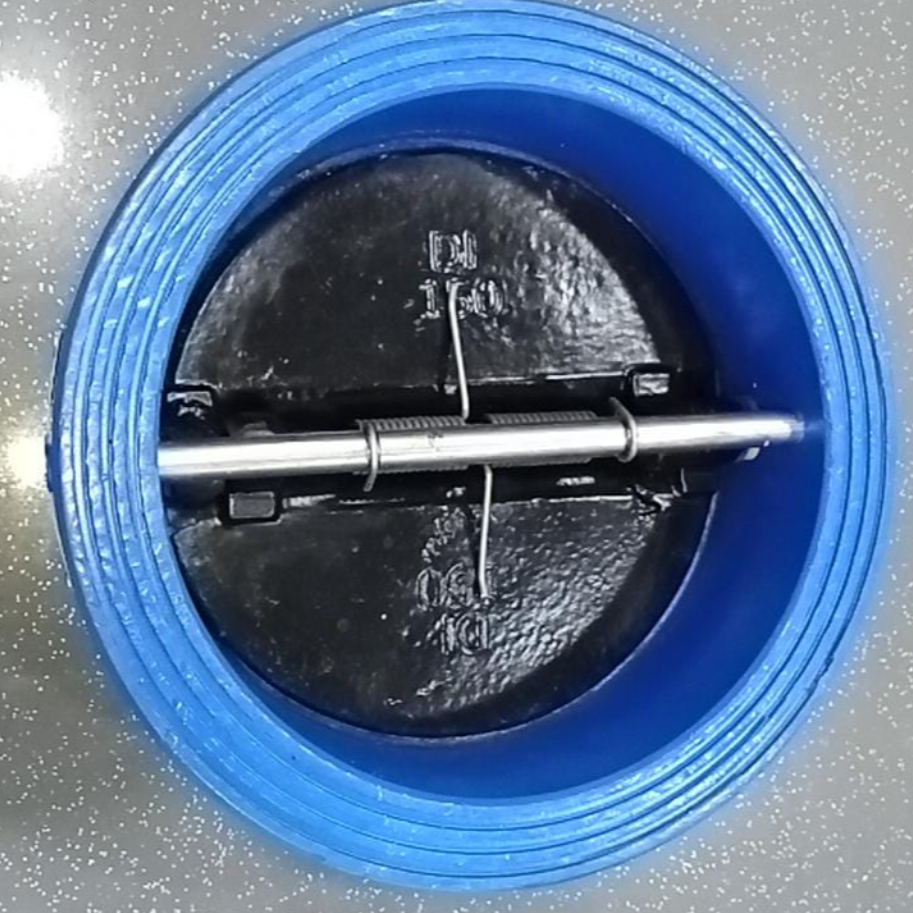

Dual Plate Check Valve best Distibutor

VA -2100 (OLD CODE VA-21)

Product - Dual Plate Check Valve

Product Standard - API 594

Body Material cum Standard - Ductile Iron (ASTM A536 Gr.60-40-18)

Product Description- Dual Plate wafer Type Swing Check Valve With Spring

Pressure Rating-16, Type Of Seat - Resilient (EPDM/ Nitrile)

type of Disc- SG Iron (GGG40), Springs - SS (AISI-304)

End Details - Suitable for Insertion Between PN10/PN16/CL150 BS 10 Table D/E/F/ Flanges Face to Face - Manufactures Standard / API 594

Test Pressure -Seat 1 bar Hyd.(Low Pressure)

Seat 17.6 bar Hyd.(Full Pressure)

Shell 24 bar Hyd.

dual plate check valve, also known as a double door or split disc check valve, is a type of non-return valve designed to prevent backflow in piping systems. It consists of two spring-loaded plates (or discs) that pivot on a central hinge pin. These plates open when fluid flows in the desired direction and close quickly when flow reverses, preventing reverse flow and potential system damage.

One of the key advantages of dual plate check valves is their compact and lightweight design, making them ideal for systems where space and weight are considerations, such as in shipbuilding, HVAC, power plants, and oil and gas industries. Their design results in lower pressure drops compared to swing check valves, enhancing flow efficiency and reducing energy consumption.

The spring-assisted closing mechanism helps minimize water hammer—a common issue caused by sudden changes in flow direction. This feature not only protects the system but also extends the valve’s service life. The valve body is typically made from materials such as cast iron, stainless steel, or carbon steel, depending on the application and fluid type.

Installation is straightforward as these valves can be mounted between flanges (wafer type), fitting easily into existing pipeline systems. They are suitable for both horizontal and vertical flows (upward only), making them versatile across different configurations.

Regular maintenance is minimal, and with the correct material selection, dual plate check valves offer excellent resistance to corrosion, erosion, and high pressure/temperature environments.

In summary, a dual plate check valve is a reliable, efficient, and cost-effective solution for preventing reverse flow in a wide range of industrial and commercial applications. Its compact design, low pressure drop, and durability make it a preferred choice in modern flow control systems.