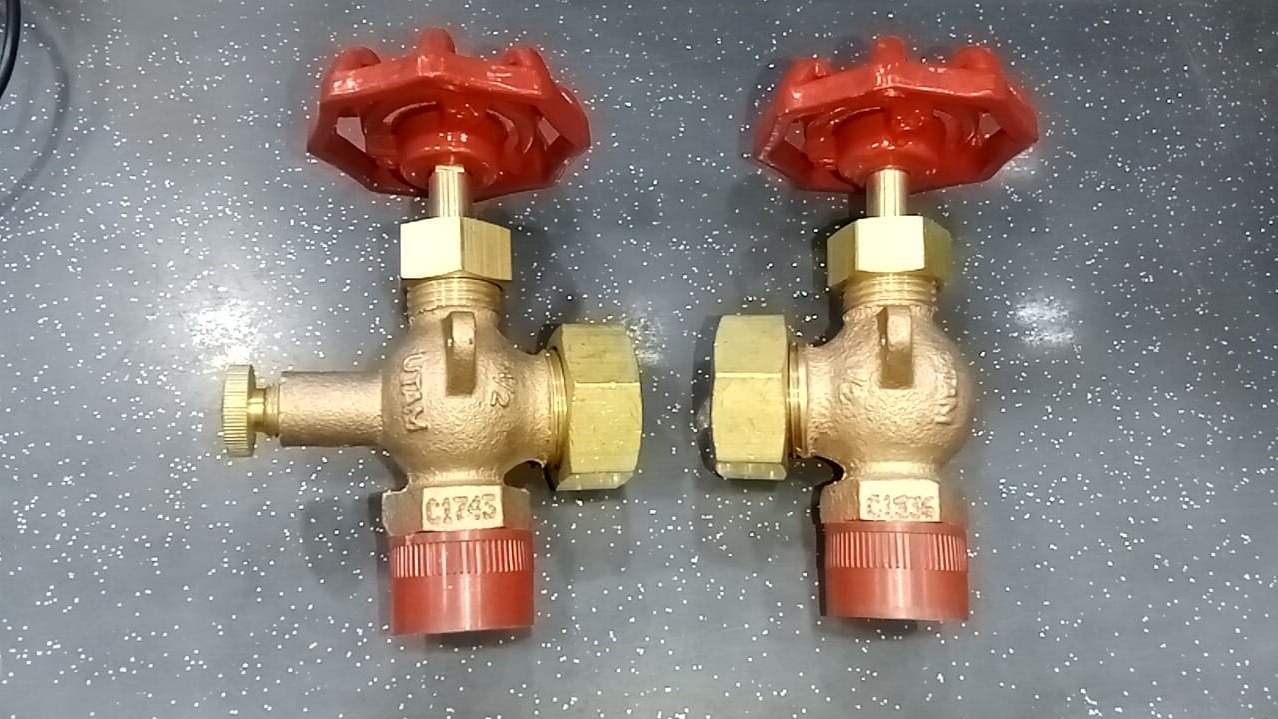

A DCB (Directional Control and Block) valve is a type of hydraulic or pneumatic valve used to control the flow and direction of fluids within a system. Here’s an overview of its key aspects:

Key Functions of DCB Valves:

Directional Control: These valves direct the flow of hydraulic or pneumatic fluid to various parts of a system. They determine the path the fluid takes, which is crucial for controlling the operation of machinery or equipment.

Flow Control: They manage the flow rate of the fluid, which can affect the speed and force of actuators like cylinders or motors.

Blocking Function: DCB valves can block fluid flow to prevent movement or to hold a position. This is important for maintaining stability and control in systems where specific positions or functions need to be held firmly.

Common Types:

Hydraulic Directional Control Valves: These are used in hydraulic systems to control the direction of hydraulic fluid, impacting the operation of hydraulic cylinders or motors.

Pneumatic Directional Control Valves: These work similarly in pneumatic systems, controlling compressed air to actuate various components.

Key Components:

Spool or Poppet: The component that moves within the valve to open or close flow paths.

Ports: Entry and exit points for fluid.

Actuator: Mechanism that moves the spool or poppet, which can be manual, electrical, pneumatic, or hydraulic.

Applications:

Manufacturing: To control automated machinery and assembly lines.

Automotive: In systems like brake controls or transmission systems.

Construction: For controlling excavators and other heavy machinery.

Aerospace: Managing hydraulic systems in aircraft.

Considerations:

Size and Flow Rating: Ensure the valve is suitable for the flow rates and pressures of your system.

Actuation Method: Choose between manual, solenoid-operated, or other types of actuators based on your control needs.

Environmental Conditions: Consider factors like temperature, exposure to chemicals, or potential for vibration.

Troubleshooting:

Leakage: Check seals and connections if there’s unexpected fluid loss.

Failure to Operate: Inspect the actuator and control signals to ensure they’re functioning correctly.

Performance Issues: Evaluate for clogging or wear in the internal components that might affect performance.

Keywords

A DCB

flow rate

fluid flow

flow paths

DCB Valves

Flow Rating

exit points

key aspects

other types

Block) valve

Common Types

Flow Control

Key Functions

various parts

control needs

brake controls

assembly lines

Key Components

compressed air

hydraulic fluid

pneumatic valve

pneumatic fluid

control signals

Actuation Method

hydraulic systems

Blocking Function

pneumatic systems

Performance Issues

various components

specific positions

hydraulic cylinders

internal components

automated machinery

transmission systems

other heavy machinery

unexpected fluid loss

Environmental Conditions

manual, solenoid-operated

Hydraulic Directional Control Valves

Pneumatic Directional Control Valves