A foam flow ball valve refers to a type of ball valve that is designed to control the flow of foam or other foam-based liquids in a variety of industrial applications. Foam is often used in fire suppression systems, and controlling its flow can be crucial in maintaining pressure, ensuring proper distribution, and ensuring safety during emergencies.

Key Features of Foam Flow Ball Valves:

Ball Valve Mechanism:

A ball valve uses a spherical ball with a hole in the center. The valve is rotated to control the flow of liquids. In foam applications, the ball valve\'s role is to either allow or restrict the flow of foam or foam-based chemicals (such as in fire suppression systems).

When the valve is fully open, foam flows freely. When closed, it stops the flow of foam.

Sealing and Material Considerations:

Since foam may be corrosive or reactive depending on the application (such as in firefighting systems where foam concentrates are used), the materials used in the valve must be resistant to corrosion and wear.

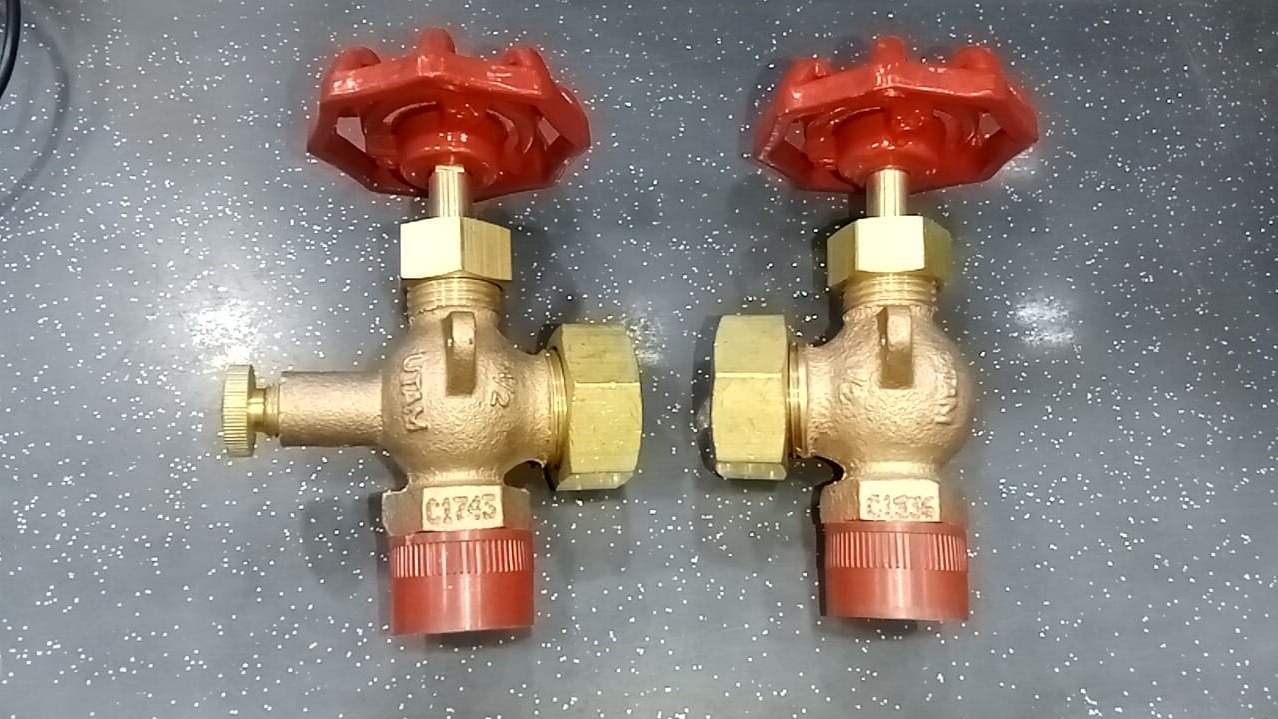

Common materials include stainless steel or brass for the valve body and specialized seals made of elastomers or PTFE (Teflon) to ensure proper sealing and durability.

Pressure and Flow Control:

In foam fire suppression systems, controlling the foam flow at a specific pressure and rate is essential for proper coverage. A foam flow ball valve can be used in combination with other components like regulators, nozzles, and pumps to maintain consistent foam output.

The valve may have pressure regulators built-in or be used as part of a larger system for regulating flow pressure.

Sizes and Configurations:

Foam flow ball valves come in various sizes (from small industrial models to large valves for fire suppression systems) to accommodate different flow rates and pressures.

They may also come in a range of configurations, including manual and automated options. Automated versions may be controlled remotely in larger systems.

Applications:

Fire Suppression Systems: Foam ball valves are commonly used in fire suppression systems where foam is deployed to extinguish fires, especially in areas like airports, chemical plants, and refineries.

Industrial Fluid Handling: Foam flow ball valves are also used in industries like the food and beverage industry, where foam control in manufacturing processes is required (for example, in breweries or dairy plants).

Oil and Gas: In some operations, foam is used for cleaning or as a stabilizing agent in drilling operations, requiring precise control over its flow.

Design Considerations:

Ease of Operation: Ball valves typically have a 90-degree rotation to open and close, making them easy to operate manually or with an actuator.

Maintenance: Like any valve, foam flow ball valves should be inspected regularly for wear and tear, especially the seals and ball mechanism.

Leak Prevention: Given the potential hazards of foam, especially in fire suppression scenarios, ensuring that the valve is leak-proof is a critical design requirement.

Advantages of Foam Flow Ball Valves:

Quick and Reliable: Ball valves are known for their reliability and quick action. They open and close faster than many other types of valves, which is crucial in applications requiring fast response times, such as in firefighting systems.

Minimal Resistance: When fully open, a ball valve offers minimal flow resistance, which can help in maintaining high flow rates of foam.

Durability: Due to the simple design and robust construction, foam flow ball valves tend to have a long operational life with minimal maintenance.

Precision Control: Ball valves can provide precise control over foam flow, especially when combined with appropriate actuators and control systems.

Maintenance and Inspection:

Inspection of Seals: Since foam can be corrosive, especially in high-concentration firefighting agents, it\'s essential to inspect seals regularly for wear and leakage.

Ball Movement: The ball inside the valve should move freely without excessive friction. Any obstructions or build-up of foam can hinder the valve’s operation.

Cleaning: Foam residue can build up inside the valve, affecting its function. Regular cleaning, especially in systems that handle large volumes of foam, is necessary to ensure consistent performance.

Keywords

foam flow

fully open

valve affecting

valve body

flow rates

flow control

foambased liquids

operations foam

foam control

foam concentrates

ball valve

ball inside

excessive friction

move freely

inspection inspection

simple design

close faster

quick action

potential hazards

operate manually

close making

90degree rotation

stabilizing agent

manufacturing processes

beverage industry

extinguish fires

controlled remotely

larger system

ptfe teflon

stainless steel

reactive depending

material considerations

foambased chemicals

ensuring safety

foam sealing

foam applications

specific pressure

spherical ball

inspected regularly

actuator maintenance

regulators nozzles

proper coverage

large valves

durability pressure

firefighting systems

wear common materials

control systems maintenance

foam durability due

industrial applications foam

inspect seals regularly

reliable ball valves

ball valves role

pressure regulators builtin

function regular cleaning

provide precise control

ensure proper sealing

specialized seals made

leakage ball movement

handle large volumes

highconcentration firefighting agents

fire suppression systems

ensure consistent performance

long operational life

dairy plants oil

airports chemical plants

small industrial models

emergencies key features