Ball Valves Dealer

Ball valves are essential components in industrial systems for controlling the flow of fluids and gases. Their robust design and reliable performance make them a popular choice across various applications, including water treatment, oil and gas, and chemical processing.

The fundamental mechanism of a ball valve involves a spherical ball with a hole (or port) through its center. This ball is mounted on a rotating shaft. When the valve is in the open position, the hole in the ball aligns with the flow path, allowing fluid to pass through with minimal resistance. When the valve is closed, the ball rotates 90 degrees to block the flow completely.

One of the standout features of ball valves is their ability to provide a tight seal, ensuring that there is minimal leakage when the valve is fully closed. This characteristic is particularly crucial in applications where a reliable shutoff is necessary, such as in hazardous or high-pressure environments.

Ball valves are known for their durability and ease of use. They typically require only a quarter-turn to open or close, which allows for quick operation. This simplicity of operation makes them ideal for systems where rapid response is essential. Additionally, their design minimizes pressure drop and turbulence within the pipeline, contributing to efficient fluid flow.

These valves come in various configurations, including full port (where the ball's hole diameter matches the pipe diameter) and reduced port (where the ball's hole is smaller than the pipe diameter). Full port valves are preferred in applications requiring unobstructed flow, while reduced port valves are often used where space or cost constraints are a concern.

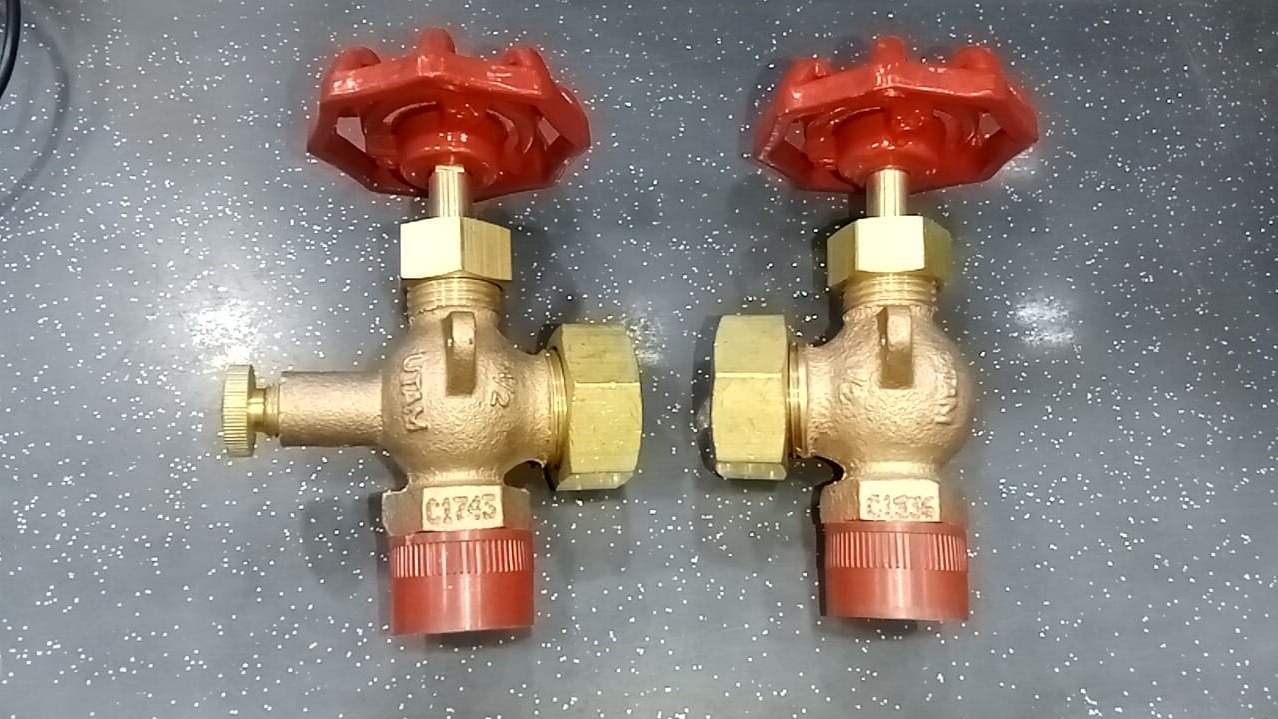

Materials used in ball valve construction include stainless steel, brass, and plastic, each suited to different environmental conditions and fluid types. For instance, stainless steel is chosen for its strength and resistance to corrosion, while plastic valves are ideal for corrosive chemicals.

In summary, ball valves offer a combination of reliability, durability, and ease of operation, making them a versatile choice for various industrial flow control applications.

#ballvalvesdealer

#BallValvesDealer

Keywords

flow path

90 degrees

tight seal

fluid types

robust design

pipe diameter

pressure drop

open position

plastic valves

spherical ball

rapid response

rotating shaft

popular choice

quick operation

stainless steel

minimal leakage

water treatment

versatile choice

cost constraints

reliable shutoff

Full port valves

standout features

unobstructed flow

minimal resistance

industrial systems

Ball Valves Dealer

corrosive chemicals

chemical processing

reduced port valves

reliable performance

essential components

various applications

efficient fluid flow

fundamental mechanism

various configurations

ball valve construction

high-pressure environments

different environmental conditions

various industrial flow control applications