Industrial Valves Dealer

Industrial valves play a crucial role in various sectors, including oil and gas, water treatment, power generation, and manufacturing. These devices control the flow and pressure of fluids within a system, ensuring efficient operation and safety.

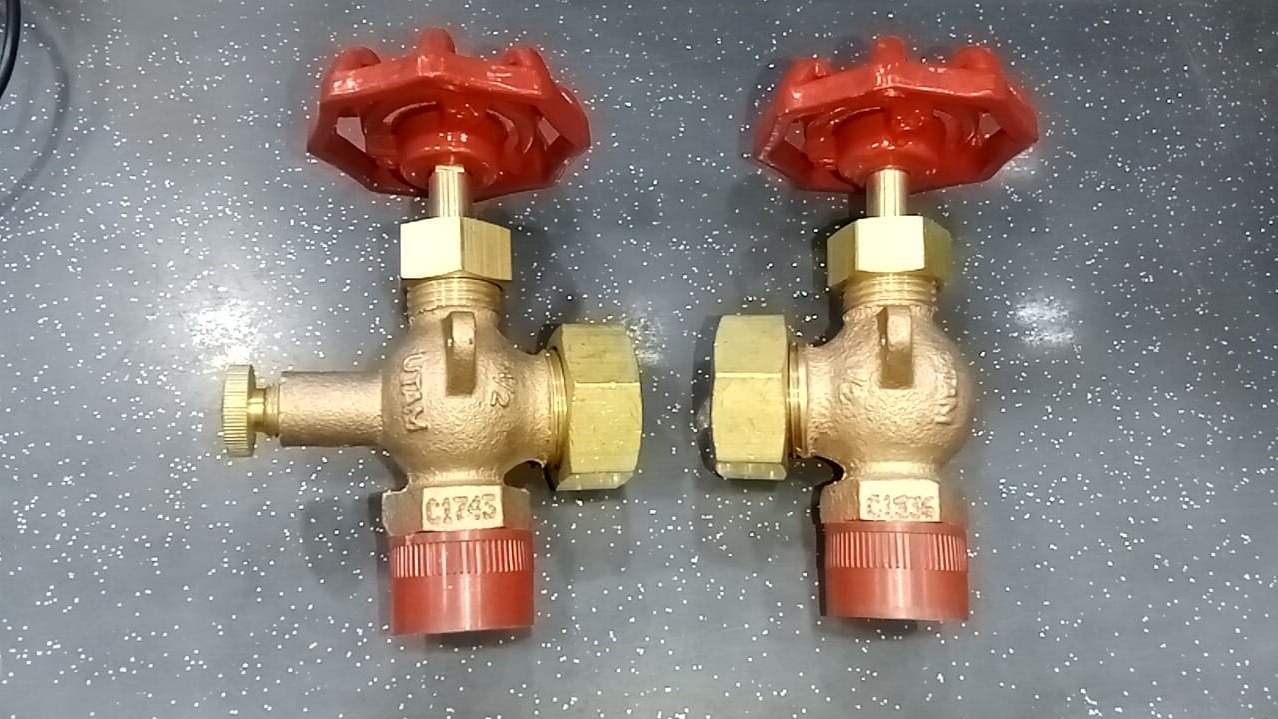

There are several types of industrial valves, each designed for specific applications. Gate valves are typically used for on/off control, providing minimal pressure drop when fully open. Globe valves, on the other hand, are ideal for regulating flow due to their design, which allows for precise adjustments. Ball valves offer quick shut-off capabilities, making them a popular choice in many processes. Check valves prevent backflow, ensuring that fluids move in the desired direction, while butterfly valves are lightweight and suitable for large volume flows.

Materials used in valve manufacturing vary widely, depending on the application. Common materials include stainless steel, cast iron, and various alloys, which provide durability and corrosion resistance. Selecting the right material is essential for ensuring longevity and performance in harsh environments.

Valves are also integral to automation and control systems. With advancements in technology, many industrial valves are now equipped with actuators and sensors, allowing for remote operation and real-time monitoring. This not only enhances efficiency but also improves safety by minimizing human intervention in potentially hazardous situations.

In addition to functionality, regular maintenance is vital for optimal performance. This includes routine inspections, cleaning, and, when necessary, replacing components to prevent leaks or failures that could lead to costly downtime.

In summary, industrial valves are indispensable in managing fluid systems across various industries. Their diverse types, materials, and integration with automation technologies make them key components in achieving operational efficiency and safety in industrial processes.

Keywords

cast iron

other hand

Ball valves

off control

Gate valves

Globe valves

crucial role

diverse types

fluid systems

several types

key components

right material

various alloys

many processes

costly downtime

control systems

stainless steel

water treatment

various sectors

Common materials

remote operation

butterfly valves

power generation

various industries

human intervention

harsh environments

large volume flows

optimal performance

valve manufacturing

routine inspections

regular maintenance

precise adjustments

efficient operation

hazardous situations

real-time monitoring

corrosion resistance

industrial processes

specific applications

minimal pressure drop

operational efficiency

many industrial valves

automation technologies

Industrial Valves Dealer

quick shut-off capabilities