Rotary Valve Dealer

Rotary valves are vital components used in various industries to control the flow of fluids or granular materials. They operate through a rotating mechanism that allows for precise regulation and reliable shutoff. Commonly used in applications such as air handling, chemical processing, and bulk material handling, rotary valves are designed to handle both gases and solids with ease.

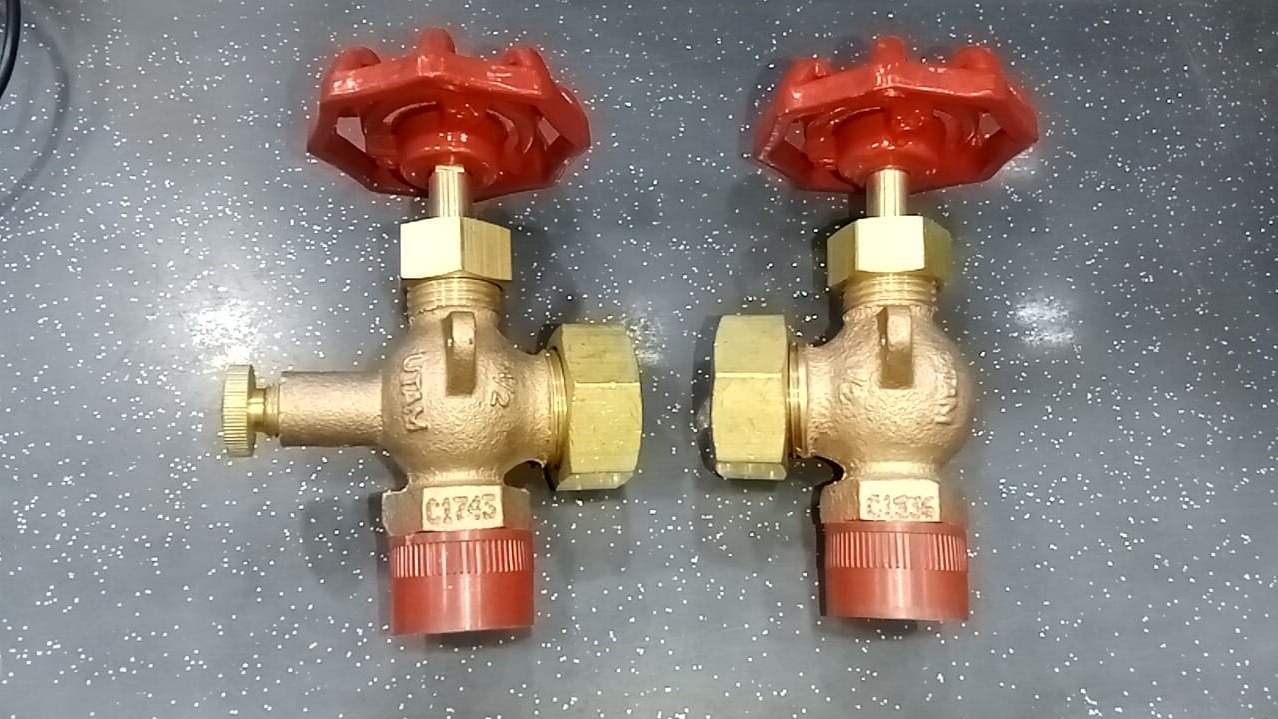

A rotary valve typically consists of a valve body, a rotating element (often a rotor or disc), and a housing. The rotor is mounted inside the valve body and rotates to open or close the passage for fluid or material flow. As the rotor turns, it either allows material to pass through or blocks the flow, depending on the valve's position.

One of the primary advantages of rotary valves is their ability to manage high flow rates and pressures with minimal resistance. This is particularly useful in systems where continuous, uniform flow is crucial, such as in pneumatic conveying systems for bulk powders. Rotary valves also excel in applications requiring precise flow control and consistent operation.

Rotary valves are available in various designs, including ball, butterfly, and plug types. Each design offers distinct benefits. For example, ball rotary valves provide tight shutoff and are resistant to wear and tear, making them ideal for high-pressure applications. Butterfly rotary valves, with their simple design and compact size, are often used in applications where space is limited.

Maintenance of rotary valves involves regular inspection of the rotating elements and seals to ensure proper operation and prevent leakage or blockage. Ensuring the valve is properly aligned and lubricated helps maintain its performance and longevity.

In summary, rotary valves are essential for managing fluid and material flow in numerous industrial applications. Their robust design and versatility make them a preferred choice for efficient, reliable control in various processes.

Keywords

valve body

plug types

compact size

bulk powders

air handling

robust design

simple design

tight shutoff

material flow

various designs

high flow rates

proper operation

rotating element

vital components

reliable shutoff

various processes

distinct benefits

regular inspection

minimal resistance

primary advantages

rotating mechanism

granular materials

various industries

precise regulation

ball rotary valves

chemical processing

Rotary Valve Dealer

consistent operation

precise flow control

bulk material handling

Butterfly rotary valves

continuous, uniform flow

high-pressure applications

pneumatic conveying systems

efficient, reliable control

numerous industrial applications